Contact Us

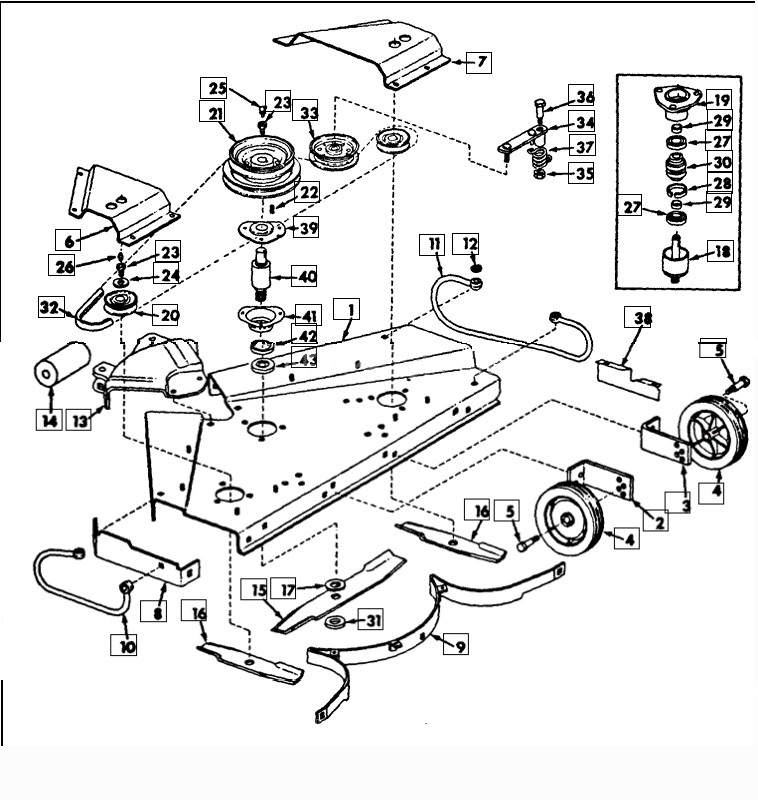

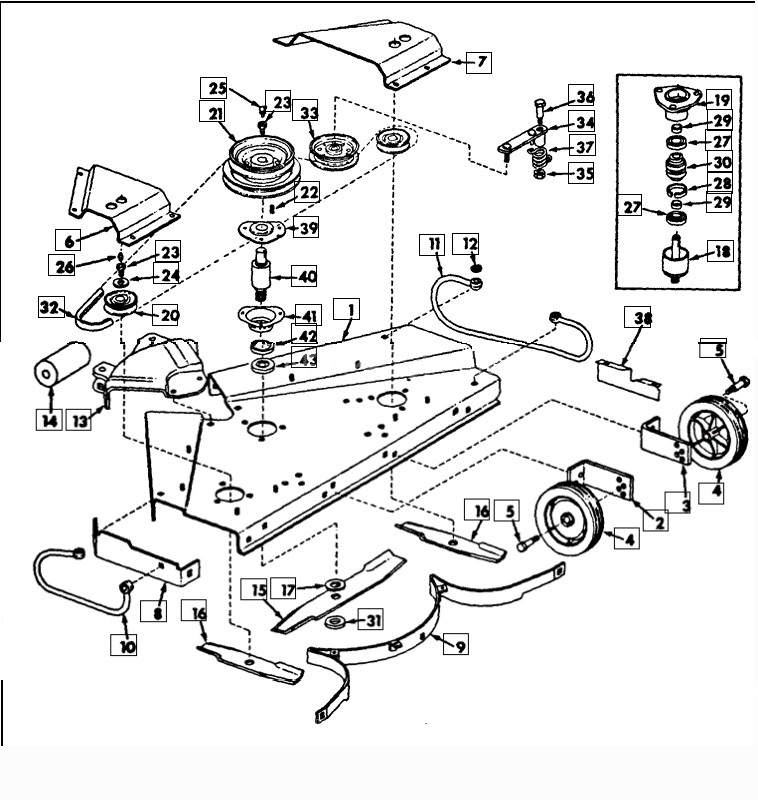

The Spindle NUT is #31 in the drawing above.

The Spindle NUT is #31 in the drawing above.

Issues:

1. Nuts won't come off

For instance:

On a recently acquired 123, one spindle nut was soooo stuck that I had to pull the center spindle (with blade attached)

out of the deck so I could mount it in a vise to try to get it loose. Nothing worked, so after stripping the points of

the nut off. I had to slice the nut with an abrasive wheel and chisel it off the shaft

(while taking great care not to hurt the spindle threads).

2. Nuts are rounded off or the Threaded end of the spindle are buggered up by hitting rocks, etc.. if the nut has worn too much.

Discussion:

I have several narrow frame cubs that have the 3 blade deck.

Annually, at the end of the season and, if needed, during the season, I remove the blades to sharpen them.

I use an air impact wrench to get them off and on.

I always use the nickel-based "Never Seize" anti seize compound when reattaching the nuts.

However, i do run into a couple of problems from time to time.

Over time, the nuts become rounded off on their "bottoms" from hitting rocks, dirt, etc..

Since the mfr decided to use the thinner "jam nut" style of nut, this rounding reduces the amount of material on the "points" of the nut.

The thinner jam nuts are also susceptible to being rounded off from ill-fitting or mis-applied wrenches and impact tools over time.